Copper Bonded Steel Rods

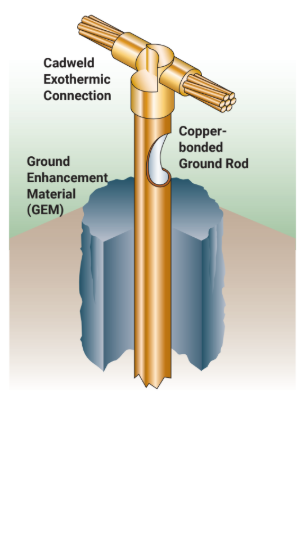

Copper Bonded Steel Rods are specially designed earthing electrodes that combine the high tensile strength of steel with the superior conductivity and corrosion resistance of copper. These rods provide a reliable, safe, and long-lasting earthing solution for diverse electrical and industrial applications.

Features

- Cold-rolled threads with continuous, unbroken grain flows preserve copper coating and are stronger than cut threads

- 99.9% pure electrolytic copper coating

- Rods have a high carbon steel core and tip that provide superior strength when driving

- Copper coating will not crack when bent or tear when driven

- Minimum copper coating of 10 mils on rods listed to UL® 467

- OEM name, length, diameter and part number is roll-stamped within 12″ (304,8 mm) of chamfered end

- UL logo and control number where applicable stamped on each rod for easy inspection after installation

Ground Enhancement Material (GEM)

Ground Enhancement Material (GEM) is a superior conductive material that solves your toughest grounding problems. It is the ideal material to use in areas of poor conductivity, such as rocky ground, mountain tops and sandy soil. GEM dramatically reduces earth resistance and impedance measurements. Furthermore, GEM may reduce the size of the grounding system where conventional methods are unsatisfactory. Once installed, GEM is maintenance-free,Earthing Solutions not requiring periodic charging or the presence of water to maintain its conductivity.

Third-party testing has been completed to verify that GEM conforms to IEC® 62561-7. This standard introduces a benchmark for electrical performance and corrosion of earth enhancement materials that has been absent from the industry to date.

OEM offers GEM Calculator software that provides resistivity values for common GEM applications and can help estimate the amount of GEM required for an installation. It operates in four languages – English, Spanish, French and German – and performs calculations in Imperial or Metric units.

Features

- Maintains constant resistance for the life of the system once in its set form

- Performs in all soil conditions even during dry spells

- Does not require periodic charging treatments or placement

- Does not require the continuous presence of water to maintain its conductivity

- Fully sets within 3 days, fully cures within 28 days

- Does not dissolve, decompose, or leach out with time

- Non-corrosive

- Reduces vandalism and theft since conductors are hard to remove from concrete

- Easy-to-handle 25 lb (11.3kg) bags or buckets

- Requires only one person to install

- Exceeds IEC® 62561-7 which sets the benchmark for corrosion, leaching, sulfur content, and other environmental regulations

- Complies to the U.S. Environmental Protection Agency (EPA) Toxicity Characteristic Leaching Procedure (TCLP), EPA test method 1311

- Can be installed using trench or ground rod backfill methods

Copper bonded Steel Conductor

The market with high quality copper-bonded ground rods. It has taken that same concept in ground rods and made this into a revolutionary new grounding conductor. The core of the Earthing Solutions Cu-Bond Round Conductor is a low carbon steel grade for improved flexibility in the field. The steel core is plated with nickel then electro-plated with a coating of copper. This electro-plating process helps ensure a long-lasting molecular bond between the copper layer and the steel.

The steel core of the conductor provides theft-deterrent benefits, making the conductor difficult to cut with hand tools. With this steel core, Cu-Bond Round Conductor is a cost-effective alternative to 100% copper conductor. The copper surface of the conductor provides high conductivity and corrosion resistance properties.

In the utility industry, the product can be used as a distribution down-lead conductor or as part of a bonding kit for substation fences or equipment ground risers back to the grid. In telecom applications, the product can be used to connect an equipment ground to the ground grid, as a riser (down-lead) for towers, or as a grounding conductor for data center mesh bonding. They are also well suited for rail applications such as trackside bonding conductors and stray current conductors, Earthing Solutions grounding kits for trackside equipment, electrical traction power, as well as in substation, wayside shelters, and communication antenna equipment.

Features

- Theft-deterrent; steel core is hard to cut with hand tools

- Cost-effective; copper bonded to a steel core minimizes the amount of copper in the cable

- Superior corrosion resistance; application life of typically 30-40 years in most soil conditions

- Copper-bonded coating will not crack or tear when the conductor is bent

- High resistance to corrosion and provides a low-resistance path to ground

- Cu-Bond Round Conductor is marked every meter (3.28′) for easy measurement in the field

- Meets the requirements of IEC® 62305-3 Edition 2 and IEC/EN 62561-2 for lightning Earthing Solutions protection applications

- Cu-Bond Round Conductors are UL certified to IEC® 62561-2