CADWELD Exothermic Welding – Permanent & Reliable Electrical Connections

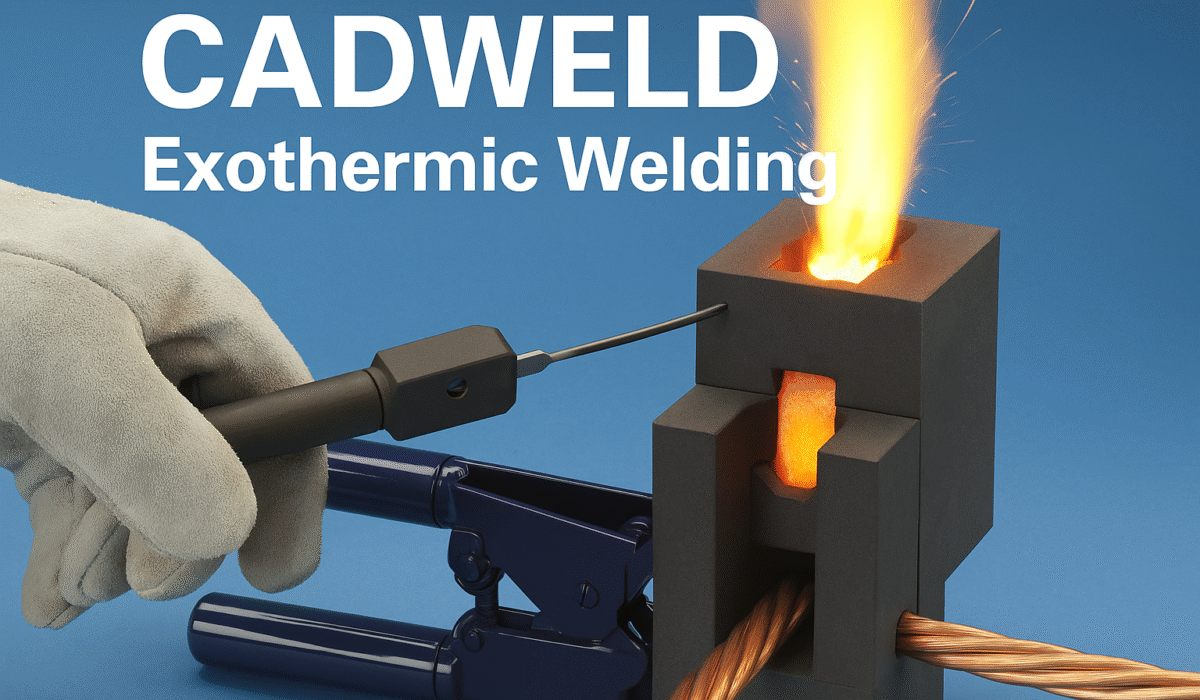

In the world of electrical safety and power distribution, reliable connections are critical. CADWELD Exothermic Welding is a globally trusted solution for creating permanent, corrosion-resistant, and highly conductive electrical bonds. Unlike traditional mechanical connectors or compression fittings, CADWELD uses a controlled exothermic reaction to fuse conductors at a molecular level, ensuring unmatched durability and performance.

What is CADWELD Exothermic Welding?

CADWELD is a chemical welding process that generates intense heat through a reaction between aluminum powder and copper oxide. This reaction produces molten copper, which flows into a graphite mold and permanently joins the conductors. The result is a molecular bond that is stronger than the conductors themselves, delivering a long-lasting, maintenance-free connection.

Key Features of CADWELD:

Permanent Connections: No loosening or degradation over time.

High Conductivity: Provides consistent low resistance.

Corrosion Resistance: Withstands harsh environments without deterioration.

No External Power Required: Self-contained, portable, and efficient.

Versatile Applications: Suitable for copper-to-copper and copper-to-steel connections.

Applications of CADWELD Exothermic Welding

CADWELD is widely used in:

Grounding and Bonding Systems: Ensures safety in electrical networks.

Lightning Protection Systems: Provides reliable earthing for protection against surges.

Power Plants & Substations: Long-term performance in critical infrastructure.

Industrial Installations: Safe and durable connections for heavy-duty systems.

Renewable Energy Projects: Reliable grounding for solar and wind power systems.

Why Choose CADWELD?

Electrical safety depends on the quality of connections. CADWELD offers unmatched reliability by eliminating common issues like loosening, corrosion, or mechanical failure. With a proven track record worldwide, it has become the preferred choice for engineers, contractors, and industries that demand safety and performance.